Categories

The primary goal of this application is to increase efficiency and reduce costs associated with inventory management. It can help you track what products are in stock, the time to reorder, and the reorder quantity. This can help improve customer satisfaction by preventing stockouts.

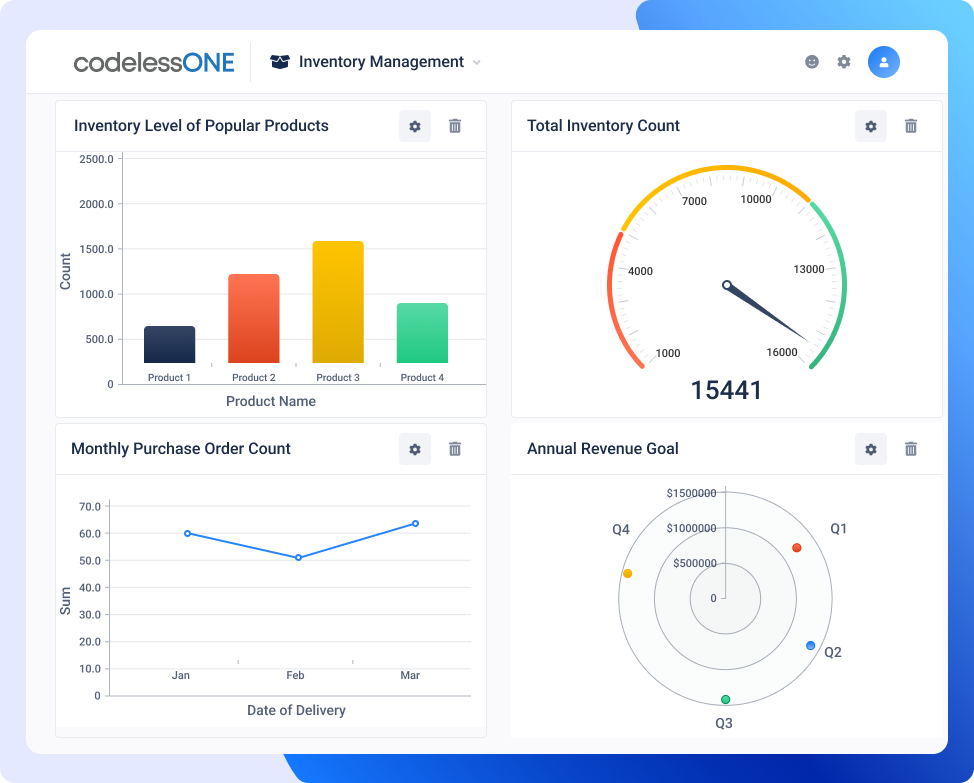

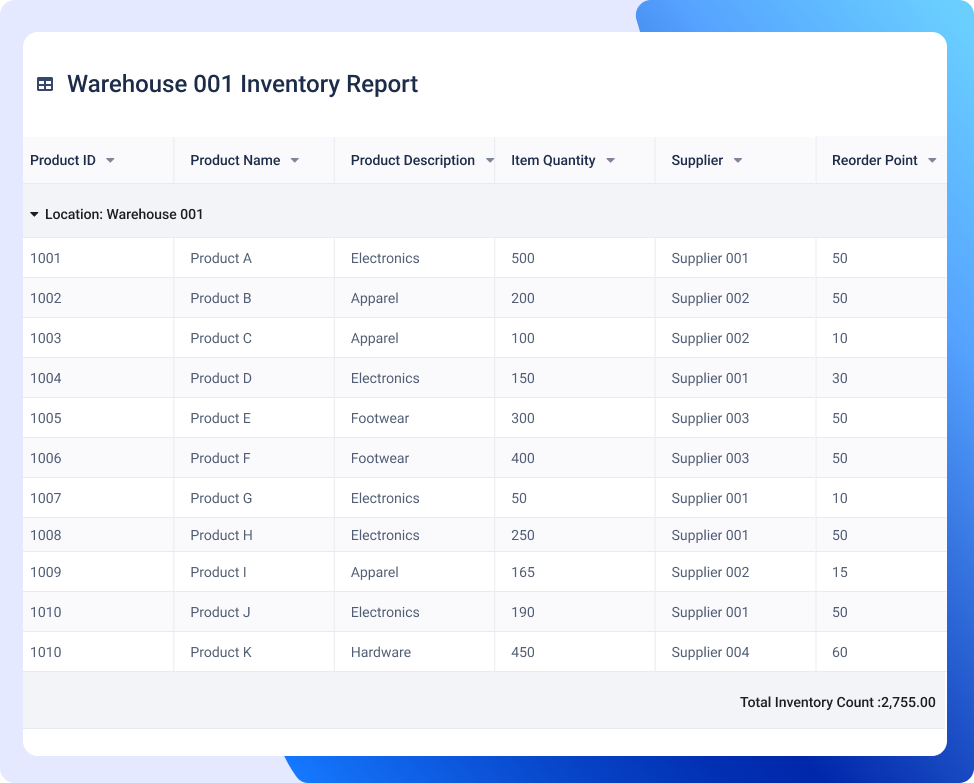

- Quickly view key inventory metrics, such as current stock levels, reorder points, and sales data.

- Conveniently identify which items are selling well, allowing for better allocation of resources.

- Monitor inventory levels across different locations or warehouses in real-time.

- Create custom dashboards to track specific metrics or KPIs.

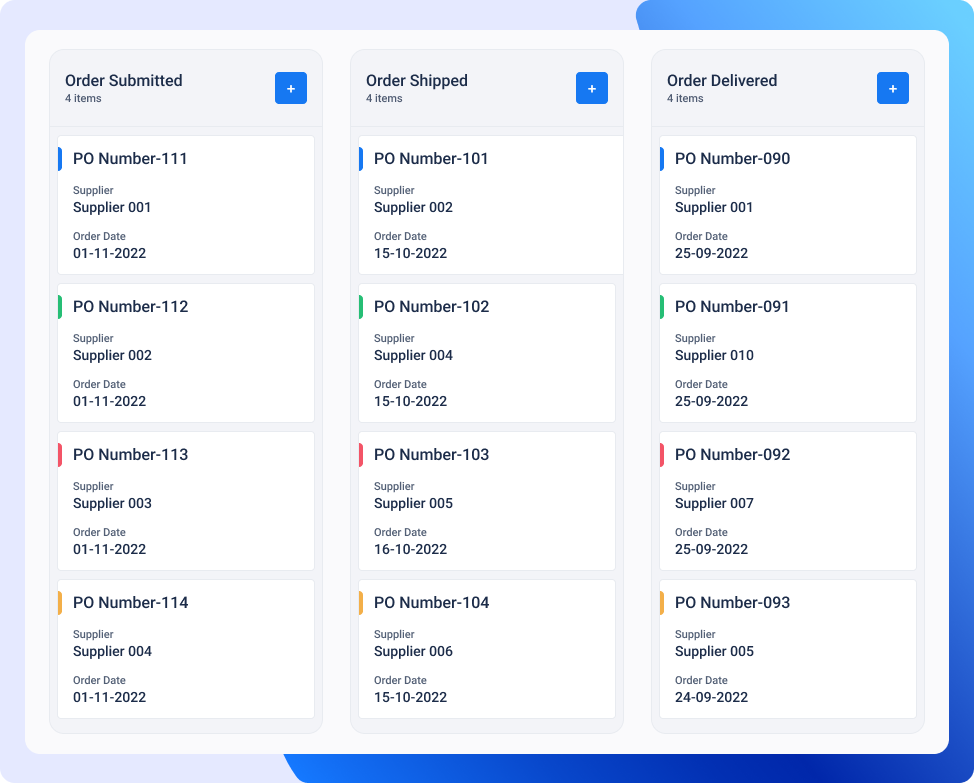

- Visualize and manage inventory items in a Kanban view, allowing easy and efficient tracking.

- Quickly identify items that are low in stock, out of stock, or need to be reordered.

- Track the progress of items through different stages of the inventory process, such as receiving, packing, and shipping.

- Easily adjust the inventory process, such as moving an item from one stage to another.

- Track inventory levels, movements, and sales in real-time, allowing for timely restocking.

- Identify trends and patterns in inventory performance over time.

- Track inventory costs, such as purchase price, storage cost, and other expenses.

- Monitor and forecast inventory demand, helping to optimize stock levels.

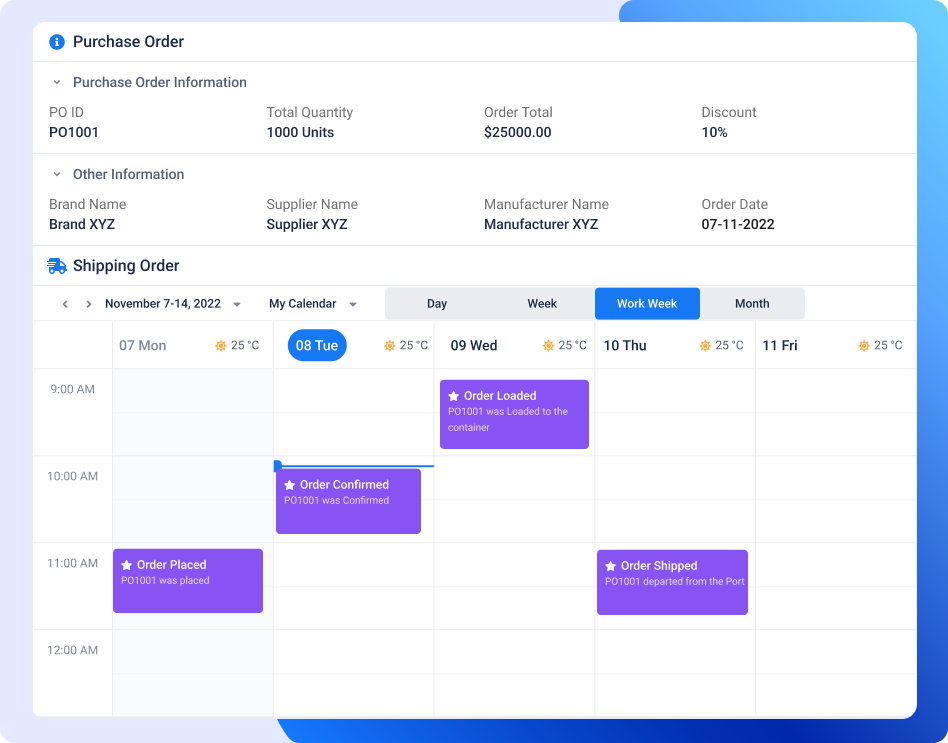

- Effortlessly view and plan for upcoming inventory-related tasks, such as restocking, deliveries, or returns.

- Quickly see when inventory is expected to arrive, allowing for better management of stock levels.

- View the entire inventory schedule for a specific period, such as a week or a month.

- Adjust the inventory schedule, such as rescheduling a delivery or return without any hassle.

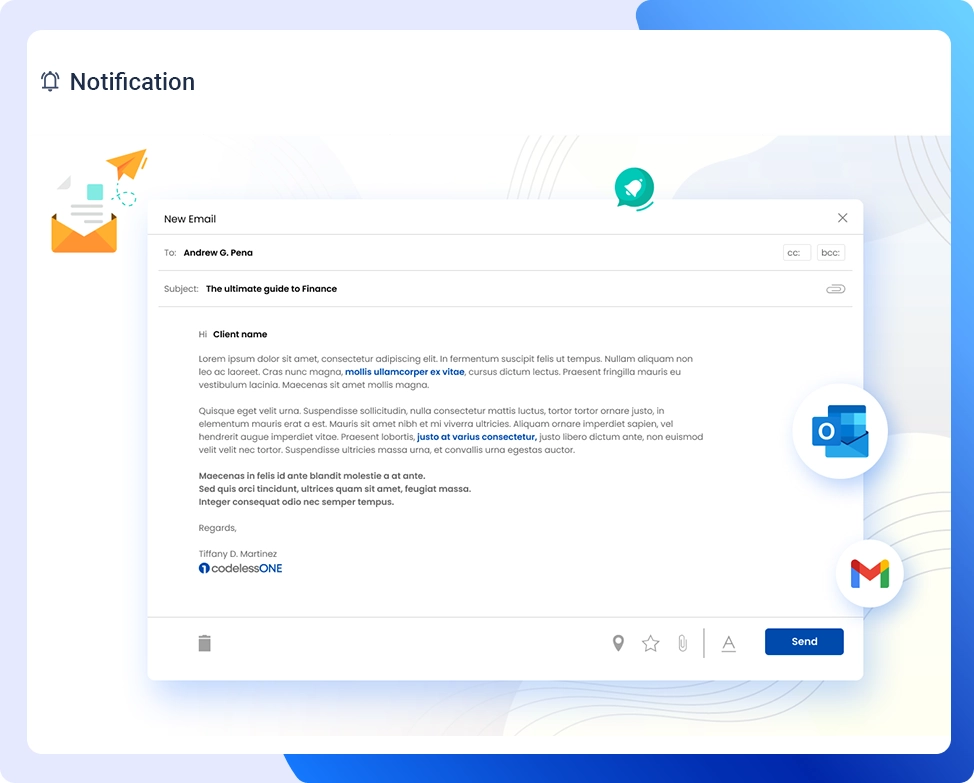

- Get real-time notifications when inventory levels fall below a certain threshold, allowing for timely restocking.

- Receive notifications when an item is out of stock, helping to prevent stockouts.

- Get alerts when an item has reached its reorder point, allowing for efficient inventory management.

- Track the delivery of new inventory with notifications when it arrives at the warehouse.

Benefits and use cases of inventory management application:

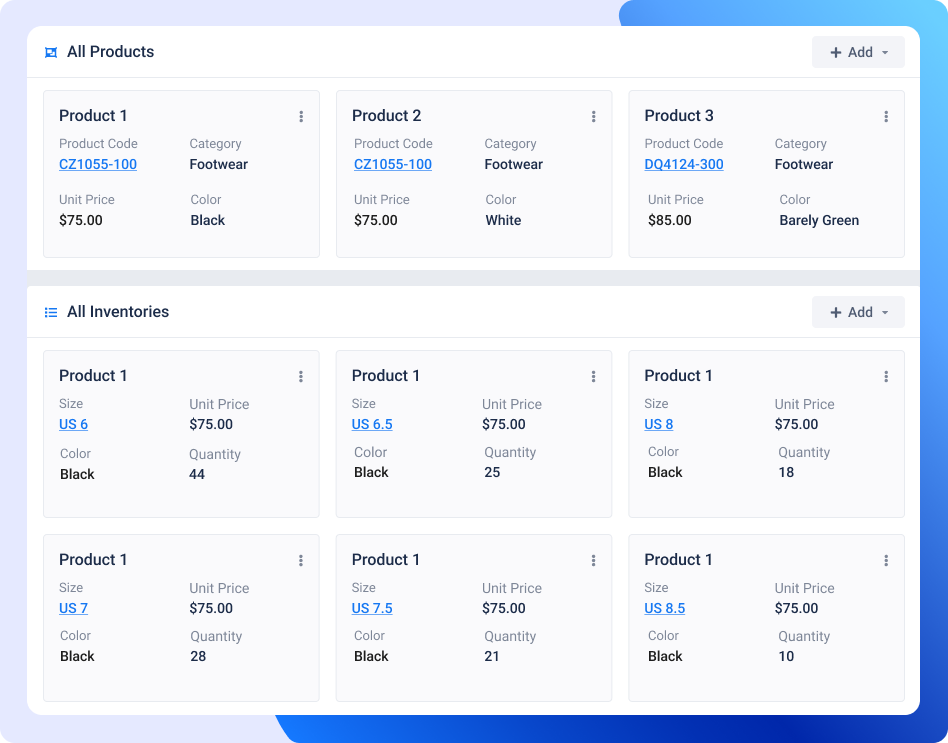

Stock tracking:

Track the quantity, location, and movement of the products in stock, including the minimum and maximum stock levels

Order management:

Manage and track purchase and sales orders and production orders.

Inventory forecasting:

Forecast future inventory needs, allowing to plan for future demand and prevent stockouts.

Multi-location management:

Manage inventory levels across multiple locations, allowing businesses to track stock levels in different warehouses or stores.